Special powder for enhancing coating products

(paints & primers)

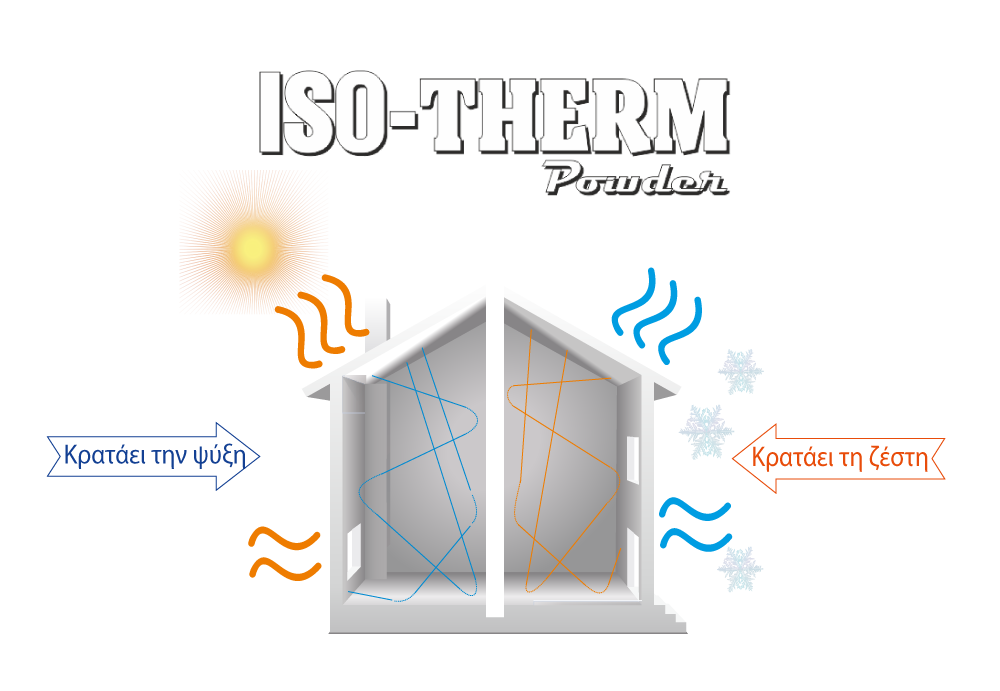

Create an interior or exterior paint with

thermal insulation properties.

When we want thermal insulation properties, add ISO-THERM

ISO-THERM is an additive, chemically inert, non-toxic,

high-tech material. It is widely used by the global industry for producing coatings, and plasters with insulating properties.

Its mixture is simple and easy

No special knowledge and equipment are required

For greater convenience during mixing, transfer the color into a larger container than the package. (e.g. for a quantity of 5

liters, choose a 10-liter container).

Add the appropriate amount of water or solvent (depending on the type of color) for greater workability (water is usually up to 10% of the total volume)

Before you mix the water or solvent with the paint, carefully add the ISO-THERM, keeping the powder container low over the liquid surface. (Because of its low specific gravity, it may raise dust).

Stir the powder with slow movements initially on the surface to homogenize the water or the solvent with the ISO-THERM.

Then, stirring deep in the container with circular movements, gradually homogenize all the material.

Touch the painted surface with your hand after application

(once it has dried) and verify the presence of the protective spheres.

What is ISO-THERM Powder

White Powder from Unbreakable Glass

ISO-THERM is a white powder made of unbreakable glass (Borosilicate glass) and is manufactured in Western Europe. It is chemically inert, non-toxic, and not hazardous for use.

Its Mixing

The mixing of ISO-THERM is simple and easy. No special knowledge and equipment are needed.

See the Technical Specifications Iso-Therm Powder

Its Morphology

Their core is hermetically sealed in a vacuum, as a result, the reinforcement with

ISO-THERM provides thermal insulation properties to any material (paint coating) to which it will be mixed.

Microscopic Glass Spheres

ISO-THERM consists of microscopic glass spheres with negative pressure inside them and an average diameter of 65 microns (as much as the diameter of a hair).

Compatible with all colors.

For interior & exterior use.

The quantity of 1000ml (1 liter) can be mixed with 5 liters of any type of water or solvent-based color.

Good to Know...!

Durability indices of interior and exterior paints.

Cool paints

With the use of ISO-THERM we achieve:

Reduction of average temperature of the load-bearing surface (wall) up to -3.25°C

The Solar Reflectance Index (SRI) is a measure of a surface's ability to reflect and reject solar heat. It is the combined value of reflectivity and emissivity. By definition, a typical black surface (reflectance 0.05, emissivity 0.90) has an SRI of 0, while a typical white surface (reflectance 0.80, emissivity 0.90) has an SRI of 100.

The emissivity of a material's surface (e) is its efficiency in emitting energy as thermal radiation. Thermal radiation is electromagnetic radiation that typically includes both visible radiation (light) and infrared radiation (IR), which is not visible to the human eye. It is expressed as a number between 0 and 1 or as a percentage. The higher thevalue, the better a surface radiates heat.

Thermal insulation indices of products (Cool white colors)

Solar reflectance index (SRI)

Surface emissivity (e)

Solar reflectance (SR)

Thermal conductivity (W/Mk)

:108

:0.89

:0.82-0.92

:0.24-0.28

Thermal insulation indices of conventional paints, for interior or exterior use, using ISO-THERM

Solar reflectance index (SRI)

Surface emissivity (e)

Solar reflectance (SR)

Thermal conductivity (W/Mk)

:114

:0.89

:0.92

:≤0,24 (+/- 7%)

Solar reflectance (SR) is the fraction of solar energy that is reflected by a roof, expressed as a number between 0 and 1 or as a percentage. The higher the value, the better the roof reflects solar radiation energy.

Thermal conductivity (W/Mk) is the property of heat transmission within a material. Depending on the ease of heat transmission, bodies (materials) are distinguished into good heat conductors, like metals and building materials, and poor heat conductors, like insulation materials.

© All Rights Reserved 2023 | InnovativeFillers.com